The internal thermal insulation steel pipe is composed of steel pipe with conveying medium + composite silicate or microporous calcium silicate + rigid polyurethane foam plastic + outer steel pipe + glass steel shell anticorrosion protective layer structure. The heat preservation treatment technology of all kinds of pipe fitting joints is mature and reliable. External style: the thermal insulation structure is composed of working steel pipe, glass wool thermal insulation layer, aluminum foil reflective layer, stainless steel fastening steel strip, guide bracket, air insulation layer, external steel pipe protection and external anti-corrosion layer. External thermal insulation steel pipe structure, steel pipe zinc-rich primer guide support high temperature resistant glass wool aluminum foil reflective layer air insulation layer outer and outer polyurethane thermal insulation steel pipe / Haidian recommended requirements and instructions: pay attention to “Hualong audio-visual” micro.

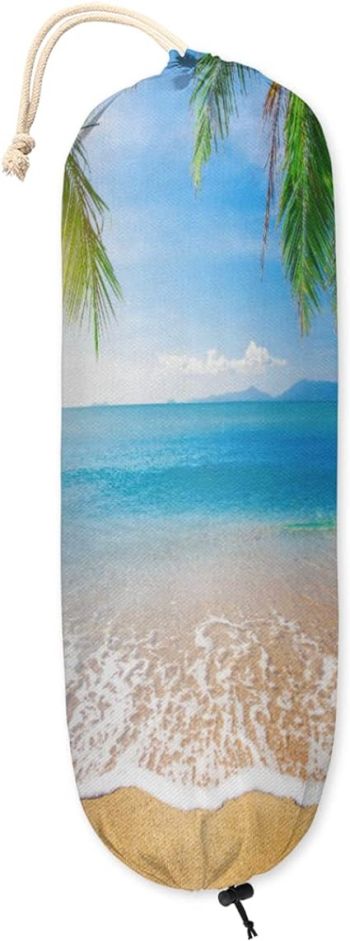

One of the primary reasons why every home should have a plastic grocery bag storage holder is the convenience it provides. Most people tend to stash away plastic bags haphazardly, often leading to a chaotic mess in pantries, drawers, or even tossed randomly around the house. Not only does this unorganized storage create a cluttered appearance, but it also makes it difficult to find a plastic bag when needed. By investing in a designated storage holder, you can eliminate this problem altogether. It offers a neat and efficient way to keep your plastic bags in one place, easily accessible whenever you require them.

The working pipe of steel sleeve steel steam insulation pipe of Hebei Youhao Pipeline equipment Co., Ltd. is generally galvanized steel pipe. when the working medium is water, steam and underground hot water, the working pipe is easy to corrode and its life is short. therefore, the urban thermal pipe network system of polyurethane prefabricated directly buried insulation pipe is in urgent need of technical innovation. With the limitations of the times, “replacing steel with plastic” is more scientifically interpreted here-when the working pipe is changed to plastic pipe, compared with metal pipe, steel sheathed steel steam insulation pipe completely solves the corrosion of chloride ion on pipeline. it has the effect of remarkable energy saving and material saving, which is in line with the current national policy of energy saving and emission reduction. At the same time, it has effectively improved the living conditions and environment, and won the support and welcome of the residents.

In the process of choosing rubber-plastic board building materials for most buildings, the main reason is that this building material can achieve better thermal insulation performance, and can prevent the impact of too low temperature on the family and work and living space in winter, and avoid the impact of high external temperature on the internal space in summer. Therefore, his isolation function is relatively perfect, which can insulate the heat or the cold, so this development makes most buildings in our country in order to create a more comfortable space, but also in order to attract people to live in, so they will choose relatively high-quality rubber board building materials to meet the basic needs of residents at the same time. Provide greater convenience for their corresponding books when working and living comfortably.

In the process, the spread of social media content has inspired a large number of novice users who want to taste something new, mostly from picnics. Senior players judge novices and veterans according to whether there are plastic bags in the camp.

The lightweight tailgate is one of our recent development priorities, and it is also the technical advantage of SABIC. Fallon said. SABIC has a full range of solutions for rear door components, from internal structure to external panels to windows. He revealed that the company is involved in a number of all-plastic tailgate projects. Replacing metal with lightweight materials in structural components such as rear door panels, front modules, door modules, seat structures and dashboards has become an important trend in the automotive industry, which also promotes the application of thermoplastics in the automotive field. The use of STAMAX resin can reduce the weight of these parts by up to 50%. Many well-known automobile manufacturers have been using this material since the beginning of this century, mainly for large molded parts and semi-structural parts.